I just cut out the back bench seat. Can somebody who has the new reduction unit from chuck tell me how far the back side (towards transom) of the prop hub is from the back of the engine? I am assuming the reduction unit bolts on where the stock cooling fan is right against the block? I need this measurement to determine how long I need my rigging to seat two people. Papee you find the pics of your throttle yet? did you take the governor off and make a plate and gasket for the hole? Also, what did you do with the oil line that runs to the governor?

|

|

Results 81 to 100 of 383

Thread: aewrigh's build

-

05-13-2013, 07:24 PM #81

Re: aewrigh's build

-

05-13-2013, 07:54 PM #82

Re: aewrigh's build

I'll call Chuck for you tomorrow an get a reference point and the total measurement. Be sure to build some adjustment into it(forward and back just in case you need to move the motor either way once you get it running. It's a way to fine tune how it runs on the water.

I have to take a pic but in one of chucks threads there is a photo, I'll look for it.

You do take off the governor and make a blockoff plate and gasket yes. I don't remember two lines but I do remember plugging at least one.Please check out our YouTube channel and subscribe! Our YouTube Channel helps fund the site. Check it out at https://www.youtube.com/channel/UCTv...FrJP7yQVFVZnyA

-

05-13-2013, 08:14 PM #83

Re: aewrigh's build

I'll get a photo when I can but here is a quick drawing of what I did. The "L" bracket attaches to a bolt that is on the intake just in front of the carb. The rod is only about 6" long.

Please check out our YouTube channel and subscribe! Our YouTube Channel helps fund the site. Check it out at https://www.youtube.com/channel/UCTv...FrJP7yQVFVZnyA

-

05-13-2013, 10:23 PM #84

Re: aewrigh's build

Thanks papee....I just got back from lowes. I purchased 5 sticks of 3/4 and 8 sticks of 1/2. That half inch stuff sure does feel flimsy. I am okay sitting on the frame but I have a couple buddies and a brother who are close to 300!!! ha ha. I know they will at least want a ride at some point. I bent out the front hoop of the cage and the rail for the seat stand. The foot platform ended up roughly 22 inches wide. Instead of having a piece of conduit running along the bottom of the boat to weld to, I will have 6-8 small pieces of channel that will fit over my side-to-side ribs making a small plate to weld to at each point.

-

05-15-2013, 03:02 PM #85

Re: aewrigh's build

I forgot to call yesterday, I called today but he wasn't in but left a message for him and to log in here. I sent him a PM explaining what you need.

EDIT: He called me back a while ago and will check in later when he gets home.Please check out our YouTube channel and subscribe! Our YouTube Channel helps fund the site. Check it out at https://www.youtube.com/channel/UCTv...FrJP7yQVFVZnyA

-

05-17-2013, 02:50 PM #86

Re: aewrigh's build

What I did to connect my bent pieces of conduit was to heat up one end red hot, then pounded a ratchet wrench socket into the end. I ended up with a tight 'male' and 'female' type joint. Then just welded it up....worked great!

Bruce

-

05-18-2013, 03:19 PM #87

Re: aewrigh's build

Thanks for the leg work papee. I am moving the boat to my buddies shop today to start welding some rigging. I can't go too far though without chucks input. I sure hope it doesn't take all summer to get a reduction unit. I told him I have money in my account just waiting to buy everything from him that I need. I ended up getting a better deal on the prop so I already have it.

-

05-23-2013, 08:16 PM #88

Re: aewrigh's build

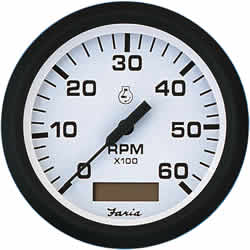

update: I guess chuck got tired of me calling and gave me the direct contact information of the machinest building the reduction units. I spoke with him and he said he should have 9 more ready within 2 weeks. Chuck said they are no longer "airboat pros" so I am not sure what that means. He never would write up an invoice for me to buy anything so dunno. I have a new question....what kind of gauges are you guys using? It is hard finding water proof gauges at a decent price. Also, I read that some tachs aren't compatible with a magneto? What are you guys using. I would rather have an analog style tach as opposed to digital. I am thinking an oil temp, oil pressure, volt, and tach would suffice? opinions?

-

05-24-2013, 09:23 AM #89

Re: aewrigh's build

OK, I'm sure it's not the case. Chuck most likely didn't have any he could touch. He mentioned to me that it would be better to wait until you have the redrive there before starting your stand which I agree with. This is not saying it can't be done, just more reliable as far as getting everything right. Chuck has a lot going on right now and I am sure when he is ready we will hear all about it.

I'm using all Faria Marine gauges, I have the white tach with the digital hour meter. The signal wire for the tach goes on the kill wire on the motor. I have oil press, oil temp, volts, tach, and fuel. I got a 12 gallon fuel cell from Summit racing with the sending unit and got the matching gauge for it. It's just one of those simple things that I like that doesn't really cost that much extra. It's nice not having to try to see through the fuel tank or stop and put a stick in it. Please check out our YouTube channel and subscribe! Our YouTube Channel helps fund the site. Check it out at https://www.youtube.com/channel/UCTv...FrJP7yQVFVZnyA

Please check out our YouTube channel and subscribe! Our YouTube Channel helps fund the site. Check it out at https://www.youtube.com/channel/UCTv...FrJP7yQVFVZnyA

-

05-24-2013, 06:20 PM #90

Re: aewrigh's build

I would have been more than happy to buy anything that he had. So maybe he didn't have anything at all. I got some measurements from the manufacturer of the reduction unit so I am just going to build the lower part of the seat stand and be a step ahead. Definitely not going to take it too far to where I can't build anything right. I have a 6 gallon topside fuel tank but I thought of getting a bigger fuel cell and adding a gauge. It would be nice for longer all day trips. I just found a faria tach that is designed for a diesel.....4000 rpm's with a mag input....sounds ideal right? Then possibly a combo gauge that has fuel, oil pressure, temp, and volts all in one. What do you guys recommend for seats? I was thinking about the cheap plastic molded seats from summit but think they might be angled back too far? Thought's or ideas?

-

05-24-2013, 07:54 PM #91

Re: aewrigh's build

This is the one I have, I'm not sure about the diesel bit, I got mine from Chuck.

If you're serious about the Faria I can pull the cover off my dash and see if I can get the model number.

I have the regular boat seats from Bass Pro on mine with the swivel and snap in deal, I can pull them right off.

I like this because if no-one is going with me I can pull a seat and save some weight. It makes a difference on these little boats.

Plastic seats would get hard after a few hours on them. I would go sith some sort of padded seats what ever you choose.Please check out our YouTube channel and subscribe! Our YouTube Channel helps fund the site. Check it out at https://www.youtube.com/channel/UCTv...FrJP7yQVFVZnyA

-

05-25-2013, 03:26 PM #92

Re: aewrigh's build

Hey papee, I began stripping my engine down yesterday evening. I have all of the sheet metal off, pulled the fan with a gear puller, etc. What do you guys do for rear motor mounts after you pull off the fan housing? Also, I see some people use the stock bracket in the front and use two motor mounts. Would it be advantageous to run 4 motor mounts? You still only have one bolt in the engine on the front of the motor. Seems to me it would be better to ditch the bracket and save the weight.

-

05-25-2013, 04:10 PM #93

Re: aewrigh's build

I have mine hard mounted, 3 mounts. Others use bushings, here is a link to Duane's build thread it has photos of the bushing style mounts. I have very little vibration with mine being hard mounted though. I used the bracket on mine and I have a long bolt in it so I can adjust the engine tilt up and down. I change mine to one spot when I'm alone and another when I have someone along. I have both spots marked so I can make the same adjustment each time I change it.

Duane's build thread.

http://miniairboatassoc.com/forum/sh...de-MiniPro-116Please check out our YouTube channel and subscribe! Our YouTube Channel helps fund the site. Check it out at https://www.youtube.com/channel/UCTv...FrJP7yQVFVZnyA

-

05-26-2013, 11:18 AM #94

Re: aewrigh's build

are you tilting your prop thrust slightly upwards to produce more bow lift with more weight in the boat or the opposite?

-

05-26-2013, 11:25 AM #95

Re: aewrigh's build

just ordered a 6k faria tach, a 4-in-1 faria gauge, throttle pedal assembly, oil cooler, and a bilge pump off of ebay. what voltage regulator do I need to get papee? I looked at several but what would be the best setup?

-

05-26-2013, 11:55 PM #96

Re: aewrigh's build

I set it to pull the bow up when having more weight, tilting the front of the motor down.

Look through Buster's build thread I think the regulator deal is in there. I know he still checks in so he may see this. If not send him a PM, I'm sure he'll point you in the right direction. it's just a matter of wiring a rectifier in but I'm not sure what he used.Please check out our YouTube channel and subscribe! Our YouTube Channel helps fund the site. Check it out at https://www.youtube.com/channel/UCTv...FrJP7yQVFVZnyA

-

05-27-2013, 03:28 PM #97

Re: aewrigh's build

papee are you using the oil pressure sender that came on the motor or did you purchase a different one to work with your gauge? or did you get a mechanical oil pressure gauge? I have never had any luck getting the pilot tube fitting to keep from leaking on mechanical ones. I am assuming that you pulled off the oil pressure switch and put a plug in its place?

-

05-27-2013, 03:29 PM #98

Re: aewrigh's build

I just removed the governor. Also, did you pull out the mechanical tach output and plug that as well or did you find some kind of cap that fit the tach ouput fitting? The shaft that drives the tach has been removed from mine so it is just an open hole.

-

05-27-2013, 03:30 PM #99

Re: aewrigh's build

I have 2 odd shaped pieces of aluminum that I might be able to make some rudders out of. What size can I get away with on my setup? Also, when people use flat sheets of aluminum for rudders, how do they do the pivot point?

-

05-27-2013, 05:30 PM #100

Re: aewrigh's build

No I have a seperate sending unit for the oil pressure and oil temp.

I didn't do anything to my tach hookup.

I like them to be 2/3 the length of the prop aproximately. I made a frame for the rudders the used conduit straps to hold it in place. I used three on the length and one at the bottom. I'll look for a photo on here.Please check out our YouTube channel and subscribe! Our YouTube Channel helps fund the site. Check it out at https://www.youtube.com/channel/UCTv...FrJP7yQVFVZnyA

Reply With Quote

Reply With Quote

Bookmarks